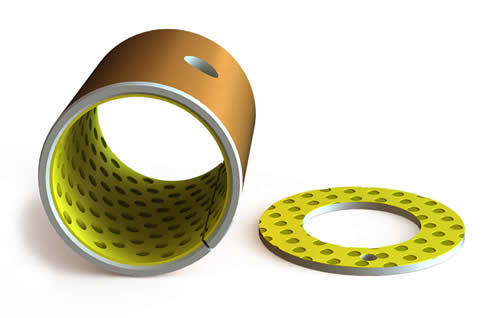

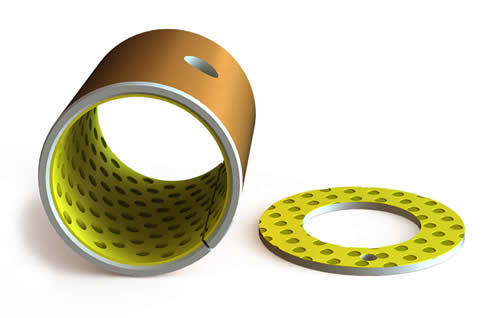

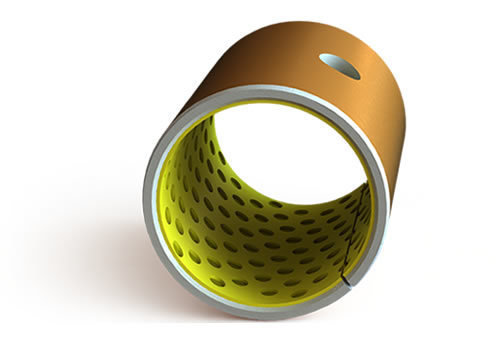

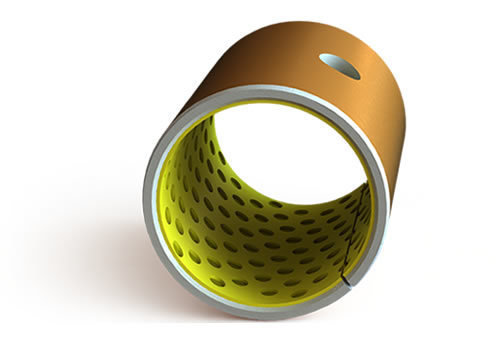

POM bearings

Minimal maintenance under severe operating conditions

POM bearings have been specially developed for marginally lubricated applications and can thus function for long periods with minimal lubrication. The POM bearings are produced according to ISO 3547.

Advantages of POM bearings

Main advantages of POM bearings include:

- Minimal maintenance

- High sliding velocity

- High load capacity

- Low friction coefficient

- Minimal bearing play

Applications of POM bearings

POM bearings are especially suited to severe operating conditions where frequent maintenance is not possible. Common applications are:

- Hydraulic applications

- Elevators

- Transportation

- Mechanical engineering

- Construction machinery

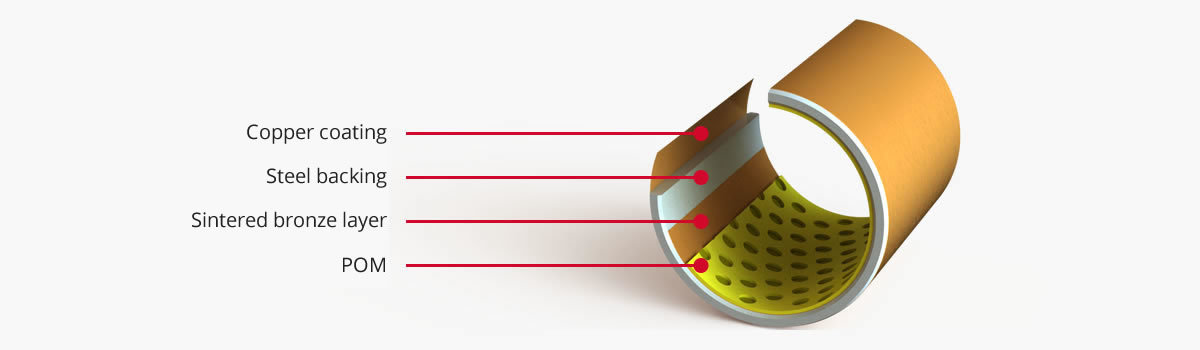

Materials

POM bearings are made from a steel backing to which a sintered bronze layer is applied. A POM top layer is then applied to this bronze layer. The bronze intermediate layer ensures efficient heat dissipation and makes for a strong joint between the steel backing and the sliding surface.

The steel backing is provided with a layer of copper or tin to prevent corrosion, while the POM top layer incorporates grease pits to retain the lubricant.

Lubrication

We recommend lubricating POM bearings with grease. The grease must contain an antioxidant for environments with temperatures over 50°C. Greases containing EP additives or significant amounts of graphite or MoS2 are not generally recommended.

Lubricating with oil is only advisable with applications in which the oil temperature does not exceed 70°C.

Specification overview of POM bearings

| Specification overview | |

|---|---|

| Properties | TX |

| Max. load (Dyn/stat), N/mm2 | 140 / 250 |

| Max. sliding speed m/s | 2.5 |

| Max. PV value N/mm2 x m/s | 2.8 |

| Temperature range, oC | -400 / +130 |

| Shaft tolerance | f7 - h8 |

| Housing tolerance | H7 |

| Shaft roughness | Ra ≤ 0.4 |

| Shaft hardness | > 200 HB |

Product finder plain bearings

Find the right plain bearings for your applications with the online product finder. Enter the values for the load, speed, inner diameter and length. You immediately get an overview of the type of plain bearings that match the entered values. This way you know exactly which plain bearings are most suitable for your application.

Need technical advice?

Are you looking for plain bearings and do you want to contact a technical advisor? Call us on 03 72 39 51 51 or send an email to info@thn.fr. We are happy to help.

Contact us