Mechanical machining of shafts

Cut to length

In our own linear machining center, the shafts are cut to length. The length tolerances are in accordance with ISO 13002.

Manual chamfer

By default, all shafts are cut to length and deburred manually.

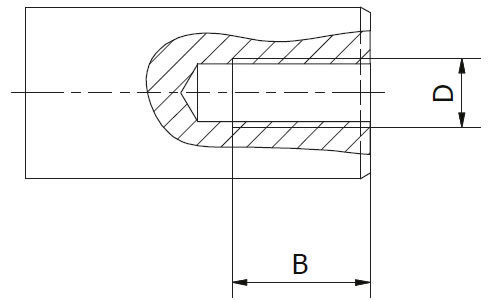

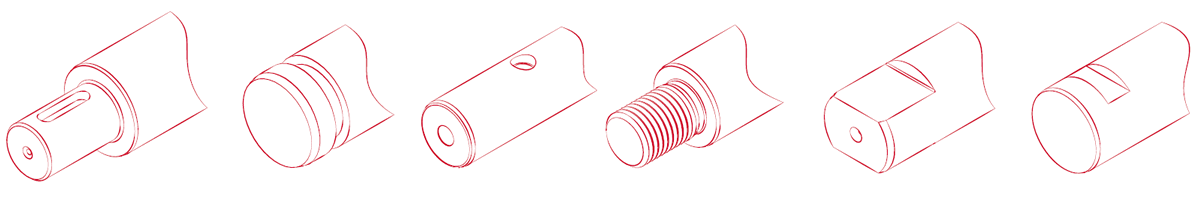

Axial and radial threaded holes

Common operations are axial and / or radial tap holes. For axial threaded holes by default we make the thread length 2.5 x D.

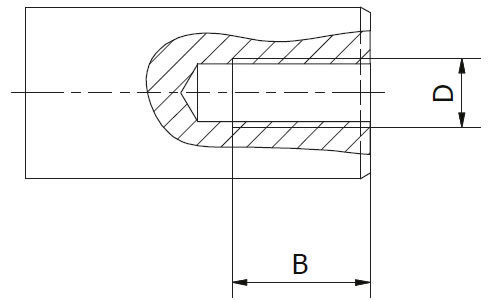

Advice and custom made shafts

In addition to standard operations such as chamfers and holes, many other operations such as holes, flat edges and keyways are also possible. We are happy to advise on the required operations and then also produce the drawings for you.

Laser engraving on hardened shafts

To maintain an overview within the production process, we can use our laser engraving machine to provide each type of shaft with a clear and permanent batch number. This ensures traceability, even for large series or complex assemblies.

In addition to standard batch numbers, customization is also possible. This includes engraving a product name, logo, or specific ID code. This makes parts easily recognizable and visually distinctive within your production environment.

Length tolerances ground shafts

| Standard length tolerances | |

|---|---|

| Shaft length La | Length tolerance |

| La ≤ 400 | ± 0,5 |

| 400 < La ≤ 1000 | ± 0,8 |

| 1000 < La ≤ 2000 | ± 1,2 |

| 2000 < La ≤ 4000 | ± 2,0 |

| 4000 < La ≤ 6000 | ± 3,0 |

* Length tolerances according ISO 13002 | ** Different length tolerances are available on request

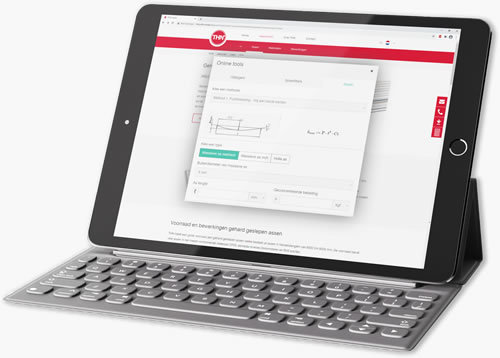

Product finder shafts

Find the right shaft for your applications with the online product finder. Enter the values you need, choose a type of shaft and the product finder will calculate the maximum deflection of the shaft. This way you immediately know which axles are most suitable for your application.

Need custom shafts?

Are you looking for hardened shafts and do you want direct contact with a technical advisor? Call us on 03 72 39 51 51 or send an email to info@thn.fr. We are happy to help.

Contact us